AUTOMATED

PROCESS CONTROL

AND INFORMATION SYSTEM

ARE YOU INTERESTED?

CONTACT US:

| Phone: | +421 2 4341 5963 |

| +421 2 4363 8407 | |

| E-mail: | office@kzsro.sk |

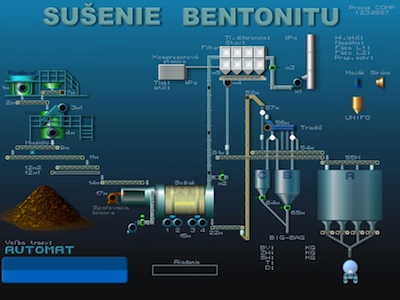

PARIS control systems

The PARIS system is intended for the creation of control applications for the monitoring and management of production in all branches of industry. The system's concept places emphasis on speed, simplicity and the repeatability of solutions. It can be implemented in small applications as well as in large-scale solutions.

BENEFITS OF THE SYSTEM:

- Operational reliability

- Data processing speed

- Simple, straightforward implementation and operation

- Easy extensibility

- Flexibility

- Distribution of system performance within the technological network

- Rapid return on investment

- Option of network connection to other ASRs

- Remote administration and servicing

ARCHITECTURE:

NCS process units (RTUs) located in measurement and instrumentation distribution panels interconnected with via QLINK process network with operator stations (PC – Central SCADA MASTER system). The cooperating stations are interconnected via the PNET network (Ethernet) and linked to the corporate LAN/WAN. Internet connectivity is a matter of course.

Our current projects

Manufacturing and supply of TD thermal cleaning equipment for clients in:

Arens, Czech Republic

Entlackungsfabrik, Germany

Tiefenbacher, Austria

Delivery of Wagner powder coating technology from Germany to a client:

Komad, Slovak Republic